|

| Tank Overfill Alarm & Tank High Level Alarm Calibration Service |

Tank Overfill Alarm System and Tank High Level Alarm System are critical safety systems on ship, especially in the case of fuel, oil, or chemical storage tank. These alarms are designed to prevent overfilling of tank, which could lead to spills, leak, or even explosion. Regular calibration and certification of tank overfill and high-level alarm system are essential to ensure their accuracy and reliability in safeguarding the ship and the environment.

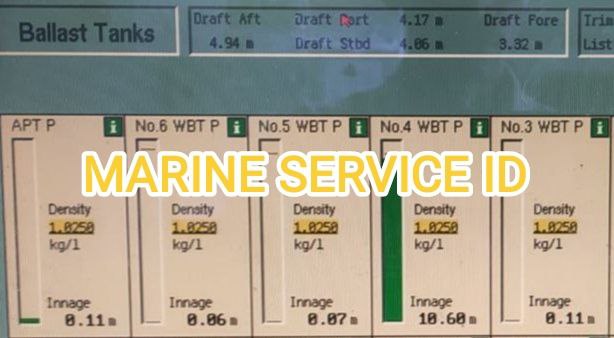

Tank Overfill Alarm System Calibration

Calibration of the Tank Overfill Alarm System or Overfill Level Alarm involves checking the accuracy and functionality of the level sensor and alarm. The calibration process typically includes filling the tank to a known level and verifying that the alarm is triggered at the correct set point. The set point is the level at which the alarm should activate to indicate that the tank is nearing its maximum capacity. Any discrepancies in the alarm activation are corrected through adjustment or repair to ensure the alarm system's accuracy and proper functioning.

|

| Overfill Level Alarm System Calibration Service MARINESERVICE.ID |

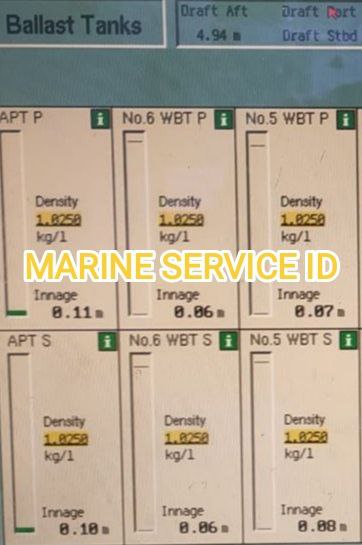

Tank High Level Alarm System Calibration

The Tank High Level Alarm System or (HLA) High Level Alarm is similar to the Overfill Alarm System but is used to indicate when the tank has reached its maximum safe capacity. Calibration of the high-level alarm system involves testing the level sensors and alarm activation at the predetermined maximum fill level. During calibration, the alarm is triggered when the tank reaches the safe capacity limit, indicating that the tank is full and should not be filled any further.

|

| High Level Alarm System Calibration Service MARINESERVICE.ID |

Certification of Tank Overfill Alarm and Tank High Level Alarm

Once the calibration process is successfully completed, both the tank overfill alarm system and the tank high-level alarm system are certified. Certification is typically conducted by a qualified marine surveyor or inspector. The certification includes providing documentation that verifies the accuracy and reliability of the alarm systems. On ship, tank overfill and high-level alarm systems must comply with international maritime regulations, ensuring their accuracy and reliability for critical safety tasks on board. The certification includes information about the calibration date, next due date for recalibration, and any limitation or restriction on the use of the alarm systems.

MARINE SERVICE ID Indonesian Ship Calibration Services

MARINE SERVICE ID has a Team of Qualified and Professional Engineers who are experienced of Overfil Level Alarm & High Level Alarm Calibration and Certification Service. We also offer Repair and Troubleshooting of Tank High Level Alarm System & Tank Overfil Level Alarm System, Annual Marine Instrumentations Calibration Service,Annual Marine Automations Calibration Service and Electronics Navigation Equipments Annual Maintenance Service at Indonesia Ports

Indonesia Marine Service MARINE SERVICE ID also provide Services of Marine Automations Calibration & Certificate,Marine Instruments Control Calibration & Certificate and Electronics Navigation Communication Equipments Annual Maintenance & Certificate, includes ;

Temperature Instruments Certificate & Calibration Service

Level Instruments Certificate & Calibration Service

Pressure Instruments Certificate & Calibration Service

Gas Detection Systems Certificate & Calibration Service

Cargo Tank Pressure Monitor System Certificate & Calibration Service

Cargo Tank Level Monitor System Certificate & Calibration Service

Cargo Tank Temperature Monitor System Certificate & Calibration Service

Oil Water Separator OWS Certificate & Calibration Service

Oil Mist Detector Certificate & Calibration Service

Ullage Temperature Interface UTI Meter Certificate & Calibration Service

Gas Detectors Certificate & Calibration Service

Available On Board Service at Indonesia Ports

For Business Inquiries Click the Link : Customers Support

Watch Video Documentation of our work about :

Tank Overfill Alarm System Calibration & Tank High Level Alarm System Calibration Video

Visit other MarineService.Id sites :

Indonesia Marine Service & Supply

Read next article from ShipCalibration.Com :